full automatic bag-given machine

Introductions:

Working process:

6-Station Rotary Weighing & Packaging Line Specification:

The full automatic bag-given packing machine is designed to meet the large enterprises, small and medium-sized enterprises to realize the automatic packaging instead of manual packaging. The operator only need to place the hundreds of bags in the bag taking device one time,this packing machine can complete the whole packing process automatically, improving the production efficiency and greatly reducing the cost. It is a multi-purpose packing machine, equipped with different counting device can pack kinds of product such as powder, liquid, granule, etc

|

|

|

The full automatic bag-given packaging machine has widely packaging range, with different feeders, it can be applied to pack the liquid, paste, powder, granules, irregular lump material, etc.

|

|

6-Station Rotary Weighing and Packaging Line Step 1: Bag feedingFeed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table. Step 2: Date printing (optional) Step 3: Opening:Open stand (flat) pouches from top and bottom with two sets vacuum caps. Step 4: Filling There is an opening detection device inserted into the open bag or pouch to expand it and detect if it is open or not. Step5: Sealing Seal the bag. Step6: cold seal outputTo make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished the production automatically. |

| Model | YY6-200-G | YY6-230-G | YY6-300-G |

| Pouch Type | Flat bag, 3-side sealing bag, 4-side sealing bag, zipper bag, standup bag, spout bag etc… | ||

| Pouch Material | Laminated film, PP, PE etc… | ||

| Pouch size | W:80-210mm L:150-300mm | W:80-230mm L:150-300mm | W:150-300mm L:150-300mm |

| Packing weight | 5-1500g | 5-1500g | 5-1500g |

| Packing Speed | 20-50Bags/Min (depends on the packing material and filling weight) | 30-60Bags/Min (depends on the packing material and filling weight) | 20-40Bags/Min (depends on the packing material and filling weight) |

| Packing Accuracy | ≤±1% | ≤±1% | ≤±1% |

| Power | 3.5KW,AC380V,50HZ | 3.5KW,AC380V,50HZ | 4.2KW,AC380V,50HZ |

| Dimensions (L*W*H) | 2200*2000*3000mm | 2200*2000*3000mm | 2770*2400*3200mm |

|

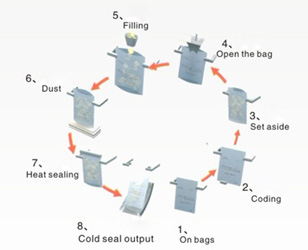

8-Station Rotary Weighing Packaging Line

Step 1: Bag feeding

Step 2: Date printing (optional) Step 3: Set aside station (zippered bag) Step 4: Opening Step5: Filling Step 6: Set aside station (adjust, dust remove, secondary feeding) Step7: Hot sealing Step8: Cold seal output |

8-Station Rotary Weighing and Packaging Line Specification:

| Model | YY8-200-G | YY8-230-G | YY8-300-G |

| Pouch Type | Flat bag, 3-side sealing bag, 4-side sealing bag, zipper bag, standup bag, spout bag etc… | ||

| Pouch Material | Laminated film, PP, PE etc… | ||

| Pouch size | W:80-220mm L:150-300mm | W:80-230mm L:150-300mm | W:150-300mm L:150-300mm |

| Packing weight | 5-1500g | 5-1500g | 5-1500g |

| Packing Speed | 20-50Bags/Min (depends on the packing material and filling weight) | 30-60Bags/Min (depends on the packing material and filling weight) | 15-30Bags/Min (depends on the packing material and filling weight) |

| Packing Accuracy | ≤±1% | ≤±1% | ≤±1% |

| Power | 3.85KW,AC380V,50HZ | 3.85KW,AC380V,50HZ | 4.5KW,AC380V,50HZ |

| Dimensions (L*W*H) | 2600*2200*3000mm | 2600*2200*3000mm | 3200*2550*3350mm |